三。金属板的现场加工,加工设备应放在平整的场地上,有利于金属板的二次搬运和直接起重;现场生产时,尽量避免采用多位置长直纹板,一般大于12米,以便于加工。r金属板的运输。

2.第二步。对于多类型、多合同的工程,彩钢板围护结构的施工过程应安排在一个独立的施工区段内连续完成。在屋面工程施工中,如果相邻区域有高于屋面的工程,应在相邻工程作业结束后开始施工,以保护屋面工程不受损坏,或不作为脚手架支撑面。

每项工程应有项目负责人、工程技术负责人、质量负责人、安全负责人、材料保管人等。在施工队下面。在整个过程中,应有二次加工组、运输吊装组和安装组。三组比例应根据工程特点确定,以配合施工进度。

彩钢板施工中安装了大量的便携式电动工具。每个小组都应配备齐全并有后援。合理配置便携式电动工具的电源接入线,是大型工程建设进度的需要。

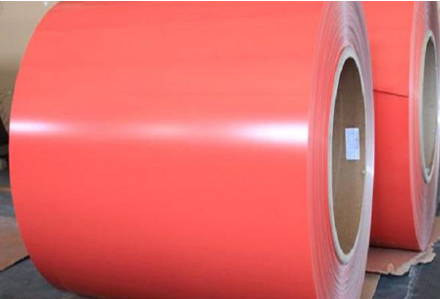

Because of the large area of the coloured steel sheet enclosure, the long single component, the finished surface decoration and other important factors, such as waterproofing, thermal insulation and aesthetics, it is important to plan thoroughly, construct cautiously and do well in construction organization and design to ensure the high quality of the task.

The construction organization design of color steel sheet enclosure structure is an integral part of the general purpose design of the project and is incorporated into the general construction organization design. Due to the particularity of color steel sheet enclosure structure, the following problems should be paid attention to in compiling construction organization design:

I. Requirements for the General Plane of Construction

1. Because the roof and strong panel have many long-length plates, the long-distance vehicle passage and vehicle rotation conditions should be prepared at the construction site.

2. Fully considering the stacking site of sheet metal, reducing the second handling, is conducive to hoisting.

3. On-site processing of sheet metal, the processing equipment should be placed on a flat site, which is conducive to the secondary handling and direct lifting of sheet metal; on-site production, multi-position long-ruled plates, generally greater than 12m, should be avoided as far as possible to steer the transport of sheet metal.

4. Conscientiously determine the starting point and construction sequence of plate installation and the number of construction teams.

5. Determine an economical and reasonable installation method, fully considering the characteristics of small weight, large length, high altitude operation and continuous movement of sheet metal.

Setting aside the necessary site for secondary processing of sheet metal is an important factor to ensure the installation accuracy of sheet metal and reduce the damage of sheet metal in the field.

II. Installation Procedures

The installation procedure of the color steel sheet enclosure structure should be located in a reasonable position in the general construction procedure of the project.

1. The Contractor shall independently arrange the construction procedure for the construction project consisting of pure sheet metal or completed independently by the sheet metal manufacturer.

2. For multi-type and multi-contract projects, the construction process of color steel sheet enclosure structure should be arranged in an independent construction section to be completed continuously. In the construction of roof engineering, if there is a project higher than the roof in the adjacent area, the construction should start after the completion of the adjacent project operation to protect the roof engineering from damage, or not be used as scaffolding support surface.

3. The coloured steel sheet enclosure structure shall enter the construction after the completion of all the working procedures of its supporting components.

4. The wall works should be started when the masonry works and decoration works under them have been completed.

5. After determining the process of enclosure structure, the construction process of roof and wall engineering should be designed.

There are many kinds of roofing projects, and the installation process has its own characteristics, but the basic process is the same.

III. Construction Organization

The construction organization plan is determined according to the size, complexity and time limit of the project.

Each project should have project leader, engineering and technical person in charge, quality person in charge, safety person in charge, material custodian and so on. Under the construction team. In the whole process, there should be secondary processing group, transport lifting group and installation group. The proportion of the three groups should be determined according to the characteristics of the project so as to coordinate with the construction progress.

Construction machinery and tools

The preparation of construction machinery and construction tools for color steel sheet enclosure structure should be done well before installation, and the mode of horizontal transportation and vertical lifting should be determined. The emphasis should be on vertical transportation. The lifting equipment of the general project can be used conditionally. When the vertical lifting equipment can not meet the transportation requirements of the sub-projects, an independent vertical should be established. Lifting equipment.

A number of portable electric tools are installed in the construction of color steel plate. Each team should be fully equipped and backed up. It is necessary for the construction progress of large-scale projects to configure the power access line of portable electric tools reasonably.