信息摘要:

彩钢板的加工必须经过剪切、冲压、弯曲、连接等工序。由于其表面有一层涂层,应特别注意加工,以防止涂层膜的损坏影响成品的外观和寿命。

1。剪切:应尽量减少切割面上的毛刺,剪切时应去除金属粉末。同时应在底部铺设橡胶垫,防止彩钢板在堆放和加工过程中出现外观损伤。

2。弯曲加工:在加工前,应清除模具和冲头零件上的污垢和铁锈;加工时应将温度控制在...

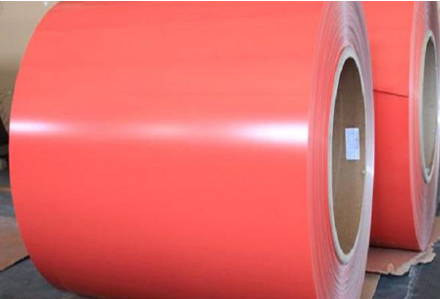

彩钢板在加工过程中的注意事项

彩钢板的加工必须经过剪切、冲压、弯曲、连接等工序。由于其表面有一层涂层,应特别注意加工,以防止涂层膜的损坏影响成品的外观和寿命。

1。剪切:应尽量减少切割面上的毛刺,剪切时应去除金属粉末。同时应在底部铺设橡胶垫,防止

彩钢板在堆放和加工过程中出现外观损伤。

2。弯曲加工:在加工前,应清除模具和冲头零件上的污垢和铁锈;加工时应将温度控制在5摄氏度以上;如果进行压辊,应使用硬质材料制作辊(淬火钢、模具钢等)或辊。硬铭文;

3。压力加工:在压力加工过程中,必须仔细选择

彩钢板的基板和涂层类型;此外,应仔细加工,金属模具的外观应特别光滑,并在表面贴上维护膜。根据情况对彩涂钢板进行表面处理,以保持涂层;

4。粘结:

彩钢板可以机械粘结、焊接和粘结,但目前彩涂钢板的焊接设备和工艺尚处于研究和试验阶段,还没有成熟的技术,用户应尽量采用机械粘结的方法。

5。

彩钢板切断段的维修:商品设计时,切断段应尽量放在隐蔽处;采用镀锌钢板做底板时,由于锌对钢材的维修有专用作用,一般不需要。对切断段进行特殊处理。只有当被药物、腐蚀性气体接触或在其他恶劣环境中使用时,切断部分才能保持。

这是

彩钢板生产过程中应注意的问题。

The processing of color coated steel sheet has to go through shearing, punching, bending and joining processes. Because there is a layer of coating on its surface, special attention should be paid to the processing in order to prevent the damage of the coating film from affecting the appearance and life of the finished product.

1. Shearing: The burrs on the cut surface should be reduced as much as possible, and the metal powder should be removed when shearing. At the same time, rubber pads should be laid on the bottom to prevent the appearance damage of the color-coated steel plate during stacking and processing.

2. Bending processing: before processing, dirt and rust should be removed from die and punch parts; the temperature should be controlled above 5 degrees Celsius during processing; if roll pressing is carried out, hard materials should be used to make rolls (quenched steel, die steel, etc.) or rolls with hard inscriptions;

3. Pressure processing: color-coated steel plate must be carefully selected for its base plate and coating type during pressure processing; in addition, careful processing should be carried out, the appearance of metal die should be particularly smooth, and maintenance film should be affixed on the surface of color-coated steel plate according to the situation, so as to maintain the coating;

4. Cohesion: Colour-coated steel plate can be mechanically bonded, welded and bonded, but now the welding equipment and skills of color-coated steel plate are still in the research and experiment period, there is no sophistication, users should try to use mechanical cohesion method.

5. Maintenance of cut-off section of color-coated steel plate: When designing commodities, cut-off should be placed in the concealed part as far as possible; when using galvanized steel plate as the base plate, because zinc has a dedicated effect on the maintenance of steel, it is generally unnecessary to make special treatment of cut-off section. The cut-off section is maintained only when it is touched by drugs, corrosive gases or used in other harsh environments.

These are the problems that should be paid attention to in the process of color coated steel plate.