信息摘要:

彩钢卷厂家带您解读彩钢卷冷却过程温度场数值模拟在冷却过程中温度的变化对组织的形成、二次相的析出和晶粒尺寸起着重要作用。因此,了解彩钢卷冷却过程中温度场变化规律具有重要的现实意义。彩钢卷比热容的计算符合实际冷却过程,建立了彩色钢卷内表面传热系数和彩色钢卷层间热阻模型。利用DEFORM-2D软件对微合金高强度彩色钢卷自然空冷过程进行了数值模拟。通过模...

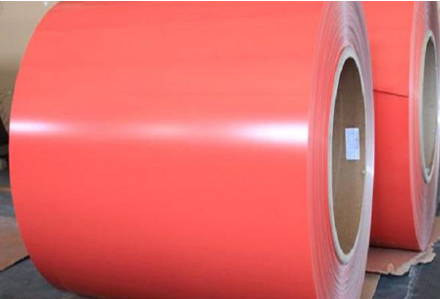

天诚彩钢卷全国配送——高端定制彩钢板——广东配送

彩钢卷厂家带您解读

彩钢卷冷却过程温度场数值模拟在冷却过程中温度的变化对组织的形成、二次相的析出和晶粒尺寸起着重要作用。因此,了解

彩钢卷冷却过程中温度场变化规律具有重要的现实意义。

彩钢卷比热容的计算符合实际冷却过程,建立了彩色钢卷内表面传热系数和彩色钢卷层间热阻模型。利用DEFORM-2D软件对微合金高强度彩色钢卷自然空冷过程进行了数值模拟。通过模拟的温降曲线与实验数据的对比,验证了

彩钢卷该模型的正确性,研究分析了钢板厚度和卷取温度对

彩钢卷冷却温度场的影响。结果表明,钢板厚度越大,

彩钢卷的温度分布越不均匀,

彩钢卷取温度越高,彩钢卷的转变时间越长,但

彩钢卷各部位的冷却速度不会太快。相应更改。

高强度钢在国民经济中起着重要作用,如汽车零部件、集装箱等应用广泛。

彩钢卷能满足更高的性能要求,降低工具自重和能耗,节约能源,减少空气污染。微合金化和控轧控冷技术是提高钢性能的主要手段。

彩钢卷取是热轧生产线控制轧制和控制冷却的最后一道工序。

彩钢卷取温度也是决定产品最终性能的重要因素。一般来说,将钢卷冷却到室温需要2到3天,测量钢卷的温度需要时间和精力。此外,由于彩钢线圈各层之间的紧密接触,彩钢线圈内部温度场难以测量。随着计算机技术的飞速发展,

彩钢卷利用有限元软件模拟彩色钢卷冷却过程中温度场的变化是最有效的方法。

The change of temperature during the cooling process of color steel coil plays an important role in the formation of structure, precipitation of secondary phase and grain size. Therefore, it is of great practical significance to obtain the law of temperature field change during the cooling process of color steel coil. The calculation of specific heat capacity of color steel coil conforms to the actual cooling process, and the model of heat transfer coefficient of inner surface of color steel coil and thermal resistance between layers of color steel coil is established. The natural air cooling process of micro-alloy high strength color steel coil is simulated by Deform-2D software. The correctness of the model is verified by comparing the simulated temperature drop curve with the experimental data, and the effects of steel plate thickness and coiling temperature on the cooling temperature field of color steel coil are studied and analyzed. The results show that the larger the thickness of the steel plate, the more uneven the temperature distribution of the color steel coil, the higher the coiling temperature, the longer the transformation time of the color steel coil, but the cooling rate of each part of the color steel coil will not change accordingly.

High-strength steel plays an important role in the national economy, such as automotive components, containers and other widely used. It can meet higher performance requirements, reduce tool self-weight and energy consumption, save energy and reduce air pollution. Microalloying and controlled rolling and cooling technology are the main methods to improve the performance of steel. Coiling is the last process of controlled rolling and controlled cooling in hot strip rolling production line. Coiling temperature is also an important factor to determine the final performance of products. Generally speaking, it takes 2 to 3 days to cool the coiled steel to room temperature, and it takes time and effort to measure the temperature of the coiled steel. In addition, the inner temperature field of the color steel coil is difficult to measure because of the close contact between the layers of the color steel coil. With the rapid development of computer technology, it is the most effective method to use finite element software to simulate the temperature field change during the cooling process of color steel coil.