信息摘要:

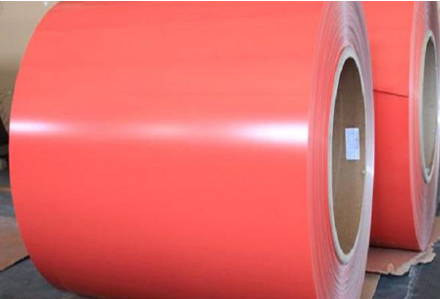

彩涂板则是将液态涂料,用刷涂或辊涂法涂覆在清洁的金属表面,加温固化后可得到不同厚度的漆膜。漆膜的作用除了把金属与腐蚀介质隔开外,还可以借助于涂料中的某些颜料(如铅丹、铬酸锌等)使金属钝化,达到永久性防腐的效果。

从彩涂板的防腐机理来看,有机涂层(包括面涂层和底涂层)是一种隔离性的物质,它将基板与腐蚀介质隔离开来,以达到防蚀的作用。...

彩涂板与镀锌板的防腐功能有什么区别?

天津天诚彩板专注彩板16年——临汾彩涂板厂家_临汾彩涂板定制 更多信息请拨打网站上方电话咨询了解。

作为卷材连续生产的工艺方法,镀锌板可以分为电镀锌和热镀锌两种方法,其中电镀锌方式是用电沉积的方法使金属表面镀上一层Zn金属或Zn合金。热镀锌也叫做热浸镀,是将被保护金属制品浸渍在熔融的Zm金属中,使其表面形成一层保护性金属覆盖层。与电镀法相比,金属热镀层较厚;在相同环境下,其寿命较长。

钢材表面热镀锌层的腐蚀相当于纯锌的腐蚀,锌在大气中的腐蚀与钢材在大气条件下的腐蚀过程相似,发生化学氧化腐蚀,在有水膜凝结的锌表面同样发生电化学腐蚀。

在中性或弱酸性的大气环境下,钢板镀锌层经腐蚀后形成的腐蚀产物为非溶性化合物(氢氧化锌、氧化锌和碳酸锌),这些产物将以沉淀形式析出,形成致密的薄既有一定厚度,又不容易溶解于水,附看性又层,一般可达8um的厚度。这种薄膜既有一定厚度,又不容易溶解于水,附着性又很强,因此它能起到大气与镀锌板之间的屏障作用,防止腐蚀的进一步发展。在保护镀锌层遭到破坏,钢铁部分表面暴露于大气环境中,此时锌与铁形成微电池,锌的电位明显低于铁的电位,锌则作为阳极对钢板基板起到牺牲阳极的保护作用,防止钢板

的腐蚀发生。

彩涂板则是将液态涂料,用刷涂或辊涂法涂覆在清洁的金属表面,加温固化后可得到不同厚度的漆膜。漆膜的作用除了把金属与腐蚀介质隔开外,还可以借助于涂料中的某些颜料(如铅丹、铬酸锌等)使金属钝化,达到永久性防腐的效果。

从彩涂板的防腐机理来看,有机涂层(包括面涂层和底涂层)是一种隔离性的物质,它将基板与腐蚀介质隔离开来,以达到防蚀的作用。

但从微观的角度来看,涂层存在着很多针孔,针孔是漆膜表面上如毛孔状的缺陷,它是陷人湿膜中的空气逸出时造成的,原因可能是湿膜表层黏度和气泡壁的界面张力过大。一般针孔的平均直径在10~10um,环境中的水、氧和其他离子都可通过针孔德入膜层,并形成局部电池,发生膜下腐蚀。针孔与涂层的厚度成反比。即厚度越薄,针孔越多。

膜下腐蚀的过程(机理)是

(1)水、离子和氧渗入有机涂层。

(2)基体金属与溶液间导电途径是电阻较低的涂层部位

3)腐蚀反应进行时,在有机涂层导电部位下面,离子的浓度增加,并生成固态的腐蚀产物。

4)铁的溶解使反应部位附近的pH值降低。

5)阴极区域的pH值升高和阳极区域的pH值降低,对有机涂层均有害处。

As a continuous coil production process, galvanized sheet can be divided into two methods: galvanizing and hot-dip galvanizing. The galvanizing method is to electrodeposit a layer of zinc metal or zinc alloy on the metal surface. Hot dip galvanizing, also known as hot dip galvanizing, is to impregnate protected metal products in molten Zm metal to form a protective metal coating on its surface. Compared with electroplating, the hot metal coating is thicker and has longer service life under the same environment.

The corrosion of hot-dip galvanizing layer on steel surface is equivalent to that of pure zinc. The corrosion process of zinc in atmosphere is similar to that of steel under atmospheric conditions. Chemical oxidation corrosion occurs, and electrochemical corrosion occurs on zinc surface with water film condensation.

In neutral or weak acidic atmospheric environment, the corrosion products of galvanized steel sheets formed by corrosion are insoluble compounds (zinc hydroxide, zinc oxide and zinc carbonate). These products will precipitate in the form of precipitation, forming a compact thin layer with a certain thickness, which is not easy to dissolve in water, appendage and layer, generally up to 8um thickness. 。 This kind of film has certain thickness, is not easy to dissolve in water, and has strong adhesion. Therefore, it can act as a barrier between atmosphere and galvanized sheet and prevent further development of corrosion. When the protective galvanizing layer is damaged and some surface of steel is exposed to atmospheric environment, zinc and iron form micro-batteries. The potential of zinc is lower than that of iron. Zinc acts as an anode to protect the steel plate from sacrificing the anode.

Corrosion occurs.

The color coated plate is a liquid coating, which is coated on the clean metal surface by brushing or roller coating. After heating and curing, varying thickness of the paint film can be obtained. In addition to separating metals from corrosive media, the function of paint film can also passivate metals with the help of some pigments in paint (such as lead, zinc chromate, etc.) to achieve permanent anticorrosive effect.

According to the anticorrosion mechanism of color coated steel sheet, organic coating (including surface coating and bottom coating) is a kind of insulating material, which separates the substrate from the corrosive medium in order to achieve the anticorrosion effect.

However, from the microscopic point of view, there are many pinholes in the coating. Pinholes are porous defects on the surface of the paint film. They are caused by the escape of air trapped in the wet film. The reason may be that the surface viscosity of the wet film and the interfacial tension of the bubble wall are too large. In general, the average diameter of pinholes is 10-10 um. Water, oxygen and other ions in the environment can enter the film through pinholes and form local batteries, resulting in corrosion under the film. The pinhole is inversely proportional to the thickness of the coating. That is, the thinner the thickness, the more pinholes.

The process (mechanism) of submerged corrosion is

(1) Water, ions and oxygen infiltrate into organic coatings.

(2) The conductive path between matrix metal and solution is the coating with lower resistance.

3) When the corrosion reaction proceeds, under the conductive part of the organic coating, the concentration of ions increases and solid corrosion products are formed.

4) The dissolution of iron reduces the pH value near the reaction site.

5) The increase of the pH value in the cathode area and the decrease of the pH value in the anode area are harmful to the organic coatings.