信息摘要:

彩涂板对背面漆的要求不高,但是相对于底漆,它还是有一定的耐候性和柔切性要求。背面漆涂在卷材的背面,主要起保护作用,同时提供外观性和一定的耐久性。要求漆膜有良好的防腐蚀性、抗划仿性、抗粘连性和加工性,但没有装饰性和户外耐久性方面的要求。

常用的背面漆有环氧型、醇酸型、聚酯型三种。前两种因为耐久性较差的原因,现已不大采用,目前,以氨基...

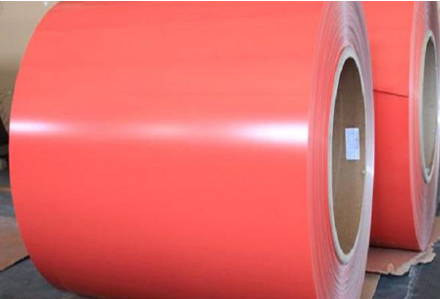

彩涂板背面漆面起什么作用,哪些涂料可以做底背面漆

天津天诚彩板专注彩板16年可全国配送——贵阳彩涂板厂家直销_贵阳彩涂板批发采购 更多信息请拨打网站上方电话咨询了解

彩涂板对背面漆的要求不高,但是相对于底漆,它还是有一定的耐候性和柔切性要求。背面漆涂在卷材的背面,主要起保护作用,同时提供外观性和一定的耐久性。要求漆膜有良好的防腐蚀性、抗划仿性、抗粘连性和加工性,但没有装饰性和户外耐久性方面的要求。

常用彩涂板背面漆有环氧型、醇酸型、聚酯型三种。前两种因为耐久性较差的原因,现已不大采用,目前,以氨基聚酯型为多。聚酯型背面漆的组成基本上与面漆相同

目前大部分的彩涂板背面漆是直接涂在经过前处理的基板上,一般不涂底漆,也可以涂装5um的底漆后再涂装背面漆。从施工和使用上划分,可将背漆分成三类

(1)防蚀性能要求较高的,基板背面涂层结构为底漆加背漆。此时的背漆主要起遮挡保护作用,可与面漆用同一品种,但性能要求比面漆低,只要求抗划伤性、抗粘连性和加工性符合要求。从经济考虑一般可用氨基醇酸树脂类作为背漆的成膜树脂,如豆油改性短油度醇酸树脂和三聚氰胺树脂背漆。

(2)彩涂板基板背面不涂底漆只涂一道背漆。此时它起着底漆和背漆的双重作用,除背漆的抗划伤性、抗粘连性和加工性外,还必须具有良好的防腐蚀性能。成膜物质一般可用环氧氨基、环氧一聚酯和聚酯一聚氨酯等。为提高背漆的防腐蚀性,除着色颜料外,在涂料中还需加人防腐蚀颜料。

(3)当预涂金属卷材主要用来制备泡沫夹心板时,背漆除要求对底漆或基板有良好的附着力和力学性能外,还必须适应夹心板的制造工艺。例如对直接注料发泡工艺,要求背漆对发泡材料有好的黏附性;对泡沫芯板粘贴工艺,;由要求背漆与所用黏合剂相匹配。成膜物一般可用环氧一聚酯或聚酯一聚氨酯。为保证对夹芯材料有足够的黏附性和生产中收卷后的防黏性,背漆中不能用降低漆膜表面张力的助剂和表面增滑剂,应该靠漆膜自身的硬度来防止收卷粘连。

The requirement of color coated board for back paint is not high, but compared with primer, it still has certain requirements of weatherability and flexibility. The back paint is applied on the back of the coil, which mainly protects the coil and provides the appearance and durability. It is required that the paint film has good corrosion resistance, scratch imitation resistance, adhesion resistance and processability, but no decorative and outdoor durability requirements.

The commonly used back coatings are epoxy, alkyd and polyester. Because of the poor durability of the first two, they are not widely used now. At present, most of them are amino-polyester type. The composition of polyester backcoat is basically the same as that of topcoat.

At present, most of the back coatings of color coated boards are directly coated on the pretreated substrates, usually without primer, or after 5um primer, back coatings can be applied. Back paints can be classified into three categories according to their construction and use.

(1) The anticorrosion performance is required to be high. The structure of the back coating of the substrate is primer and back paint. Back paints at this time mainly play a protective role and can be used with the same variety of topcoat, but the performance requirements are lower than topcoat, as long as scratch resistance, adhesion resistance and processability meet the requirements. Amino alkyd resins can be generally used as film-forming resins for back paints, such as soybean oil modified short oil alkyd resins and melamine resin back paints.

(2) No primer is applied on the back of the substrate, only one back paint is applied. At this time, it plays a dual role of primer and backcoat. In addition to scratch resistance, adhesion resistance and processability of backcoat, it must also have good corrosion resistance. Film-forming substances can be generally used in epoxy amino, epoxy-polyester and polyester-polyurethane, etc. In order to improve the anticorrosive property of back paint, besides coloring pigments, anticorrosive pigments should be added to the paint.

(3) when the pre coated metal coils are mainly used to prepare foam sandwich panels, the backing paint must also be adapted to the manufacturing process of the sandwich panels in addition to requiring good adhesion and mechanical properties to primers or substrates. For example, the direct injection foaming process requires the backing paint to have good adhesion to the foamed material; the foam core board bonding process; the required backing paint is matched with the adhesive used. Film-forming materials can be generally used in epoxy-polyester or polyester-polyurethane. In order to ensure enough adhesion to sandwich materials and anti-adhesion after winding in production, no auxiliaries and surface sliding enhancers can be used to reduce the surface tension of paint film in backcoat, and the hardness of paint film itself should be used to prevent winding adhesion.